The Lean Startup by Eric Ries is a must read for any entrepreneur, manager, or small business owner who is interested in launching a new product or service. Ries’ method is a simple approach to new product development without wasting time on an elaborate business plan. Below are the five principals to the Lean Startup Method.

Entrepreneurs are Everywhere:

An Entrepreneur does not have to work for themselves and a startup does not have to be based in a garage. Large companies can have entrepreneurs and startups within their company. Entrepreneurs can be found anywhere.

Entrepreneurship is Management:

According to Ries, Entrepreneurship is the management of dealing with extreme uncertainty. Most people think of management in a stable environment, as in a well-established company, but startups also need management. They just need a different kind of management.

Validated Learning:

You might spend time developing a product only to find out that nobody wants it. The time might seem wasted but you have learned something. You have learned what the customer doesn’t want. The concept behind The Lean Startup is to create an MVP (Minimally Viable Product) and get it out to some customers quickly so you can get feedback and learn what those customers want. This may seem like a bad idea, because what if the product has bugs in it and it fails because of the quick release. On the other hand, if you spend a year developing a product that is perfect in your eye and then you find out after the release that nobody wants it, you have wasted a year instead of only a month or two.

Innovation Accounting:

To have success with a startup, you have to focus on innovation accounting. Milestones need to be setup, and ways to measure progress need to be determined. If you are not measuring your progress you have no way of knowing how the startup is doing.

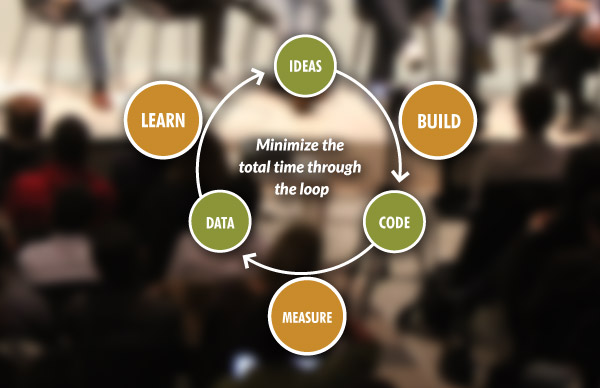

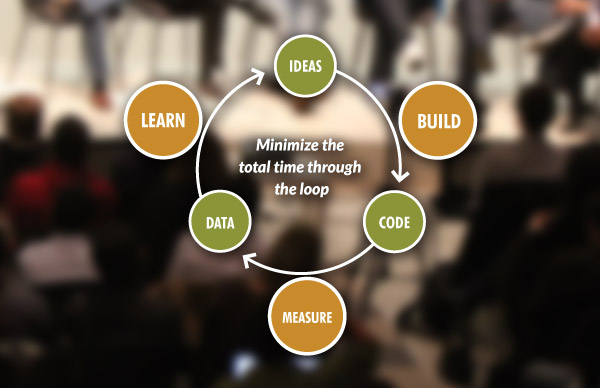

Build-Measure-Learn:

Build, measure, and learn ties in with validated learning and innovation accounting. As you are developing a new product, you need to test it with customers and measure its success. Learn from the customers and find out what they like and dislike. The quicker the process of build, measure and learn can happen, the better. As you learn about your product, you have to make the decision to either persevere or pivot. Meaning, you stay the course with your product or you need to go in a different direction.

Along with these five principles, Ries discusses implementing lean manufacturing techniques such as: andons, batch production, kanban, and pull systems. By implementing his principles along with these common lean techniques you can improve the way your startup operates.

To learn more about The Lean Startup visit: www.TheLearnStartup.com

This book review was written by Fortiviti team member, Casie Nelson.

This book review was written by Fortiviti team member, Casie Nelson.

Posted in Fortiviti Book Club, Small Business Resources